The addition of zinc or tin to copper produces the alloys bronze and brass, which are stronger than unalloyed copper. Lead and tellurium improve chip breaking, while aluminum and silicon alter the metal’s strength and malleability properties. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

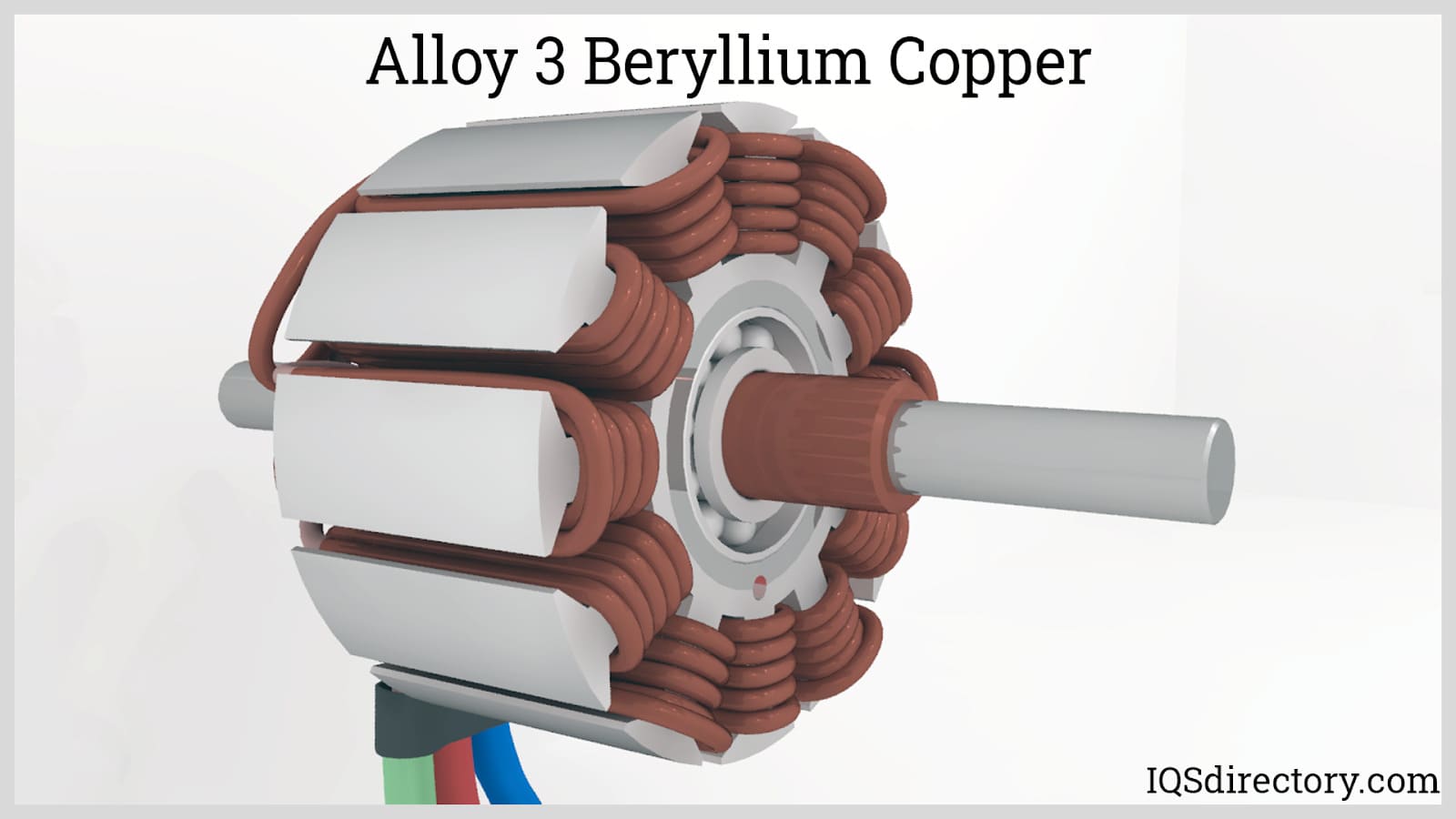

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

At ABC Metals, we are dedicated to delivering high-quality copper products that meet the diverse needs of industries worldwide. We work with a wide range of copper materials, from pure copper to specialized alloys, to provide solutions that excel in conductivity, durability, and corrosion resistance.

At Southern Copper & Supply Company, we have built our reputation on delivering high-quality copper products and dependable supply solutions to meet the diverse needs of our customers. We specialize in sourcing, processing, and distributing copper in various forms, from raw stock and sheet material to precision-cut and custom-fabricated components.

More Copper Suppliers

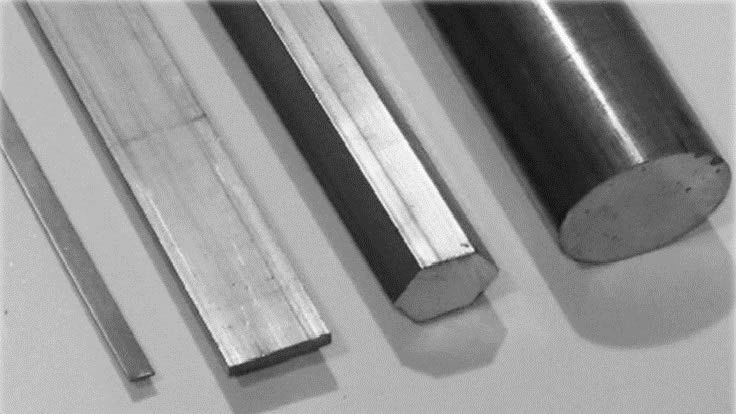

Copper suppliers usually fabricate preforms in a couple different configurations-wire, which is thin and bendable, sheets, which are flat and easily bent, tubes, which are round, hollow profiles, and rods and bars, which are solid, long and have differently shaped, uniform profiles. Copper is a highly desirable metal for its attractive color and finish, electrical and thermal conductivity, resistance to oxidation and rusting, and its ability to handle continuous exposure to chemicals, extreme temperatures and moisture. It is also quite flexible and malleable, making it easily machined and formable.

Copper and its alloys are supplied to many different industries, including the automotive, architectural, building construction, electronics, food processing, marine, aerospace, wiring, power generation, lighting and telecommunications industries. The preforms are fabricated into piping systems, propellers, hardware, kitchen products, small springs, wires, adapters, electrical connectors, lighting, valves, coins, offshore drilling equipment, microchips and roofing. It is also a non-sparking metal, which is a highly valuable property in applications inside hazardous areas that have exposure to combustible or explosive vapors and gases, like oil rigs.

Copper is formed and fabricated 3 different ways; they are cast, wrought, or pressed and sintered copper in powder form. The casting process involves heating the copper preform until it becomes molten and injecting or pouring it into a metal mold that is in the shape of the desired product. These products are usually three dimensional, complex in design and have a high degree of repeatability. Wrought copper has been mechanically deformed with or without the application of heat. These processes include drawing and extrusion, which forces a copper bar or rod through a mold with the profile of the desired product. This creates large amounts of excess waste material, which is easily recycled within the plant.

Other fabrication processes include stamping, rolling, forging, cutting, etching and engraving. Post fabrication processes include annealing, which alters the hardness levels of the copper/alloy, polishing and surface cleaning. Brass products that are exposed to outdoor environments are almost always coated in a clear varnish, which provides protection as well as a shiny finish.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services