Brass, also known as Copper Alloy 356, is used widely due to its versatility. It comprises approximately 62% copper, 36% zinc, and trace amounts of lead. Brass, unlike other metals, has a rich brown hue that makes it an ideal material for decorations. It’s common in air, gas, plumbing, and hobby applications. Brass is used in radiator components, ammunition casings, and various hardware. It is not as resistant to corrosion as stainless steel, but is softer and easier to fabricate. Brass is also nonmagnetic, making it an important component in the manufacture of clocks and electrical parts for circuits. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

At ABC Metals, we are dedicated to delivering high-quality copper products that meet the diverse needs of industries worldwide. We work with a wide range of copper materials, from pure copper to specialized alloys, to provide solutions that excel in conductivity, durability, and corrosion resistance.

At Southern Copper & Supply Company, we have built our reputation on delivering high-quality copper products and dependable supply solutions to meet the diverse needs of our customers. We specialize in sourcing, processing, and distributing copper in various forms, from raw stock and sheet material to precision-cut and custom-fabricated components.

More Brass Tubing Suppliers

Comprehensive Guide to Brass Tubing: Types, Applications, Benefits & Buying Insights

Brass tubing is an exceptionally versatile material, widely used across industries for its unique blend of durability, corrosion resistance, and aesthetic appeal. Whether for industrial manufacturing, architectural design, or artistic projects, understanding the various types, applications, and advantages of brass tubes can help buyers, engineers, and designers make informed purchasing decisions. This comprehensive guide explores the key aspects of brass tubing, from alloy types and cleaning best practices to use cases, selection criteria, and sourcing tips.

Types Of Brass Tubing

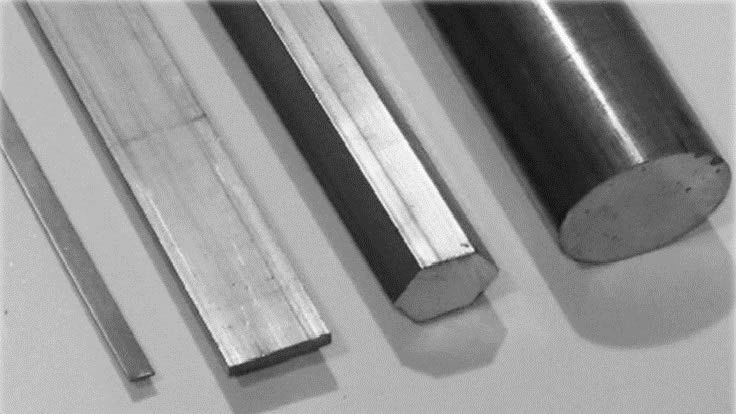

Brass tubing is available in several alloy compositions, each engineered to address specific performance requirements and environmental conditions. Selecting the right type of brass tube is crucial for optimal results in your project, whether you are seeking corrosion resistance, machinability, or a particular visual finish. Below are the most common brass tubing types:

-

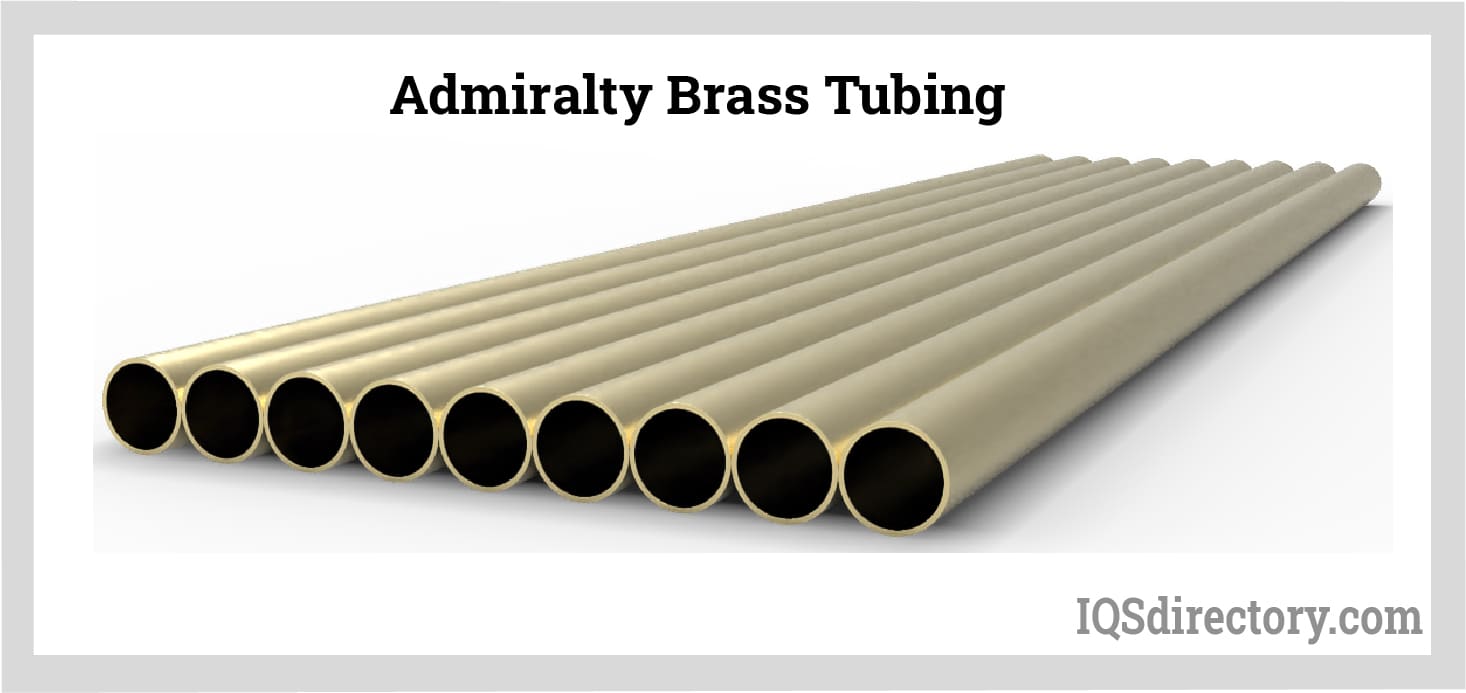

Admiralty Brass Tubing: Admiralty brass is a specialized copper-zinc alloy, with a typical copper-to-zinc ratio of 70% to 30%, and a critical addition of tin for enhanced corrosion resistance. This alloy also contains a small percentage of arsenic to prevent dezincification, making it exceptionally durable in challenging environments. Admiralty brass tubing is widely used in shipbuilding, marine environments, heat exchangers, oil well pumps, condensers, distillers, and other mechanical systems that demand long-term reliability and resistance to saltwater corrosion.

- Commercial Brass Tubing: This broad category encompasses brass alloys containing approximately 65% copper and 35% zinc (sometimes referenced as C26000 or "Cartridge Brass"). Commercial brass tubing is prized for its excellent cold working characteristics, ease of fabrication, and cost-effectiveness. Its versatility makes it ideal for general engineering, plumbing, agricultural machinery, sanitation components, radiator cores, and decorative fixtures, meeting a wide range of industrial and architectural needs.

-

Aluminium Brass Tubing: Aluminum brass incorporates a small percentage of aluminum (typically around 2%) into the copper-zinc matrix. This addition significantly increases resistance to corrosion, especially from seawater and brackish environments. Aluminum brass tubes are commonly specified for cooling water systems in land and marine power plants, heat exchangers, offshore platforms, desalination plants, water processing equipment, and other applications where durability is paramount.

Other Brass Tubing Alloys and Variants

- Free-Cutting Brass Tubing (C36000): Contains higher lead content for improved machinability, making it ideal for precision components and fittings.

- Red Brass (C23000): Features a higher copper content, imparting a reddish hue and superior resistance to dezincification, commonly used in plumbing and architectural applications.

- Yellow Brass: Known for its bright gold-like appearance and used extensively in decorative projects, musical instruments, and hardware.

Cleaning Brass Tubes

Brass tubing is often selected for indoor applications due to its attractive, lustrous finish. To maintain its ornamental value and performance, regular cleaning is essential. Here are best practices for cleaning and maintaining brass tubes:

- Use a weak acid such as white vinegar or citric acid diluted in water to gently remove dirt, tarnish, and oxidation.

- Avoid conventional household cleaners containing high levels of ammonia, which can damage the brass alloy over time.

- For polishing, choose specialized brass cleaning compounds or soft, non-abrasive cloths to preserve the surface finish.

- Apply a protective wax or lacquer after cleaning to minimize future tarnishing and reduce maintenance frequency.

- For industrial brass tubing, ensure cleaning agents are compatible with the alloy composition and intended application.

Want tips on restoring antique brass tubes or maintaining high-gloss finishes on decorative brass tubing? Explore our expert cleaning guides for detailed instructions and recommended products.

Common Questions About Brass Tubing Maintenance

- How often should I clean brass tubes in exterior applications?

- What is the best method for removing oxidation from brass tubing used in plumbing?

- Are there eco-friendly cleaning solutions for industrial brass tube systems?

Applications Of Brass Tubing

Brass tubing’s unique combination of strength, ductility, and corrosion resistance makes it a go-to material for engineers, architects, builders, and craftsmen. Below are common and specialized use cases for brass tubes:

- Heat Exchange Systems: Brass tubing is widely used in heat exchangers for buildings, ships, oil wells, and industrial cooling systems due to its superior thermal conductivity and corrosion resistance.

- Agricultural Fittings and Water Processing: Its durability and non-reactive nature make brass tubes ideal for agricultural irrigation, water processing heat exchangers, desalination plants, and water supply systems.

- Architectural and Interior Design: Brass tubes are featured in decorative elements such as railings, frames, staircases, light fixtures, and custom furniture, offering both function and a timeless visual appeal.

- Musical Instruments: The excellent acoustic properties of brass tubing are harnessed in the manufacture of French horns, trumpets, trombones, tubas, and saxophones, contributing to their rich, resonant sound.

- Precision Engineering and Fabrication: Brass tubing is used for bushings, bearings, and moving mechanical parts, especially where reduced friction and wear resistance are required.

- Engraving and Artisanal Work: When supplied as flat sheets or thin-walled tubes, brass can be engraved or shaped into jewelry, signage, and fine art pieces.

- Automotive and Aerospace: Utilized in radiator cores, fuel lines, and instrument panel components for its combination of strength, formability, and vibration resistance.

- Plumbing and Sanitation: Red brass and admiralty brass tubing are frequently specified for potable water lines, fittings, and valves due to their resistance to dezincification and microbiological contamination.

Brass Tubing in Modern Industry

With its adaptability and broad performance envelope, brass tubing is essential in sectors ranging from construction and transportation to renewable energy and high-end consumer products. Looking to compare specific brass tube applications by industry? Browse our in-depth industry use cases for tailored recommendations.

Advantages Of Brass Tubing

Brass tubing is favored by professionals for a range of compelling reasons. Here are the primary benefits of using brass tubes in your next project:

- High corrosion resistance: Brass tubes resist rust and tarnish even in hostile or marine environments, making them ideal for long-term installations.

- Excellent machinability and formability: Brass can be easily cut, bent, threaded, or shaped to custom specifications, reducing fabrication costs and lead times.

- Thermal and electrical conductivity: Brass conducts heat and electricity effectively, supporting applications in electronics, heat exchangers, and instrumentation.

- Aesthetic versatility: Available in a range of finishes (polished, brushed, antiqued), brass tubing enhances the appearance of modern and traditional spaces alike.

- Antimicrobial properties: Brass naturally inhibits the growth of bacteria and microbes, making it suitable for healthcare, food processing, and plumbing systems.

- Durability and strength: Brass tubing withstands mechanical stress, vibration, and repeated handling, ensuring reliability over decades of use.

- Recyclability: Brass is fully recyclable and retains its properties, contributing to sustainable manufacturing and green building standards.

- High friction coefficient: This enables its use in bearings, gears, and moving parts where controlled friction is required.

Why Choose Brass Tubing Over Alternatives?

Compared to other metal tubing materials such as copper, stainless steel, or aluminum, brass offers an optimal balance of cost, performance, processability, and aesthetics. Curious how brass tubing compares for your specific application? Contact our experts for a free material selection consultation.

Disadvantages Of Brass Tubing

While brass tubing offers numerous advantages, it is important to consider potential drawbacks when selecting materials for your project:

- Sensitivity to environmental pH: Brass can tarnish or corrode if exposed to highly acidic or alkaline conditions over extended periods.

- Potential toxicity: Certain brass alloys may contain lead or other elements that can leach in specific environments. Always verify material certifications for potable water or food contact use.

- Gradual erosion: Prolonged exposure to moisture, oxygen, or aggressive chemicals may cause surface wear or dezincification.

- Cost considerations: Brass is generally more expensive than plain carbon steel or aluminum, though its longevity and reduced maintenance can offset initial costs.

- Weight: Brass tubing is heavier than aluminum or certain plastics, which may be a factor in weight-sensitive applications.

Decision Factors in Brass Tubing Selection

- What are the operating temperature and pressure requirements for my brass tube application?

- Will the brass tubing be exposed to seawater, chemicals, or extreme weather?

- Is aesthetic appearance or finish a critical factor in my project?

- Are there regulatory or safety standards (e.g., NSF, RoHS) to consider?

- What fabrication processes (cutting, bending, joining) will be required?

Frequently Asked Questions About Brass Tubing

- How do I choose between admiralty brass and aluminum brass tubing for marine use?

- Can brass tubing be welded, and if so, what techniques are recommended?

- What are the common sizes and wall thicknesses available for industrial brass tubes?

- How does brass tubing compare in cost and lifespan to stainless steel tubes?

- Where can I buy custom-cut or fabricated brass tubing for architectural projects?

Conclusion: Why Brass Tubing Remains a Top Choice

Brass tubing, as a copper and zinc alloy, addresses the shortcomings of pure copper or zinc by offering exceptional strength, durability, and workability. When properly cared for, brass tubes resist rust, corrosion, and tarnishing, making them ideal for demanding environments and high-visibility installations. Understanding the differences in copper-to-zinc ratios and alloying elements is essential for selecting the right type of brass tube for your needs. With its versatility across industries and applications, brass tubing remains a preferred choice for engineers, builders, artisans, and manufacturers alike.

For those seeking to optimize their material selection or compare suppliers, partnering with an experienced brass tubing supplier can ensure you receive the best alloy and dimensions for your application. Not sure which brass tubing is right for your project? Consult with our team of experts for personalized recommendations and technical support.

Choosing the Correct Brass Tubing Manufacturer

When sourcing brass tubing for industrial, commercial, or decorative applications, it is vital to select a reputable and experienced manufacturer who can meet your quality, specification, and delivery requirements. Here are key factors and actionable steps for buyers evaluating brass tube suppliers:

- Evaluate technical capabilities: Does the manufacturer offer the alloy grades, tube sizes, and finishes you need?

- Check certifications and compliance: Ensure suppliers meet industry standards (ASTM, ISO, RoHS) for quality and safety.

- Review production capacity and lead times: Can the supplier handle your volume and meet project deadlines?

- Assess value-added services: Look for custom fabrication, precision cutting, bending, and finishing services.

- Request samples and technical data sheets: Compare product quality and performance before placing a large order.

- Compare pricing and warranty terms: Evaluate total cost of ownership, not just initial purchase price.

To ensure you achieve the best results when purchasing Brass Tubing, compare at least six suppliers using our curated list of brass tubing manufacturers. Each supplier’s business profile highlights their technical experience, manufacturing capabilities, and quality assurance processes. Use our convenient contact forms to request quotes, ask technical questions, or discuss custom project requirements directly with the manufacturer.

Interested in a side-by-side comparison of leading brass tube suppliers? Access our supplier comparison tool for detailed insights on pricing, lead times, and service offerings. Ready to request a quote? Use our RFQ form to reach multiple brass tubing companies with a single message, saving you time and ensuring you find the best partner for your needs.

If you have further questions or want expert guidance on selecting the right type of brass tubing, reach out to our team today. We are committed to helping you find the optimal solution for your brass tube requirements, from material selection to final installation.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services