Brass is a metallic alloy that is made up of copper and zinc. It has been used for centuries in a wide range of applications due to its unique combination of properties. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

At ABC Metals, we are dedicated to delivering high-quality copper products that meet the diverse needs of industries worldwide. We work with a wide range of copper materials, from pure copper to specialized alloys, to provide solutions that excel in conductivity, durability, and corrosion resistance.

At Southern Copper & Supply Company, we have built our reputation on delivering high-quality copper products and dependable supply solutions to meet the diverse needs of our customers. We specialize in sourcing, processing, and distributing copper in various forms, from raw stock and sheet material to precision-cut and custom-fabricated components.

More Brass Suppliers

How Brass Is Created and Variations in the Process

Brass, a widely utilized non-ferrous alloy, is primarily composed of copper and zinc. The manufacturing process of brass typically involves melting copper and zinc together in a controlled furnace environment. Traditionally, copper is melted first, then zinc is added to achieve the desired composition. However, brass production is not limited to these elements; the introduction of other metals such as lead, tin, or even nickel creates a range of brass alloys with enhanced properties. Understanding these variations is crucial for selecting the right type of brass for specific industrial, decorative, or engineering applications.

Leaded Brass

Leaded brass is produced by adding small amounts of lead to the copper-zinc blend. This alloy is especially valued for its superior machinability, making it a preferred choice in the manufacture of complex components requiring intricate machining, such as plumbing fittings, fasteners, and precision-turned parts. Leaded brass also exhibits improved friction characteristics, reducing wear and tear in moving assemblies. If you're comparing leaded brass vs. standard brass, consider its advantages for high-speed machining and automatic screw machine operations.

Tin Brass

Tin brass is formed by incorporating tin into the copper-zinc matrix. This variant of brass stands out for its enhanced corrosion resistance, particularly in marine and industrial environments where exposure to moisture and chemicals is a concern. Tin brass has a warm, gold-like yellow hue, making it attractive for both functional and decorative uses. When evaluating materials for marine hardware, valves, or architectural accents, tin brass offers an excellent balance of durability and aesthetics. Curious about tin brass vs. bronze? Both have excellent corrosion resistance, but their mechanical properties and cost may guide your selection.

The method of melting, alloying, and pouring brass influences the properties of the final alloy. Each casting technique delivers distinct advantages and considerations, as outlined below. Choosing the right process is essential for manufacturers and buyers aiming for cost-efficiency, precision, or aesthetic quality.

Sand Casting

Sand casting is a traditional and economical manufacturing process for brass parts. In this method, a sand mold is created around a pattern of the desired shape, then molten brass is poured into the cavity. While sand casting can yield rougher surface finishes and less precise geometries, it remains ideal for producing large quantities of simple or robust components. Sand cast brass is often used in hardware, plumbing parts, and large decorative items. Are you researching cost-effective brass casting methods? Sand casting offers a balance of scalability and affordability, particularly for less intricate designs.

Die Casting

Die casting involves injecting molten brass under high pressure into reusable steel molds. This advanced process produces parts with smooth surfaces, tight tolerances, and detailed features. Die casting is the preferred manufacturing method for complex shapes such as gears, valves, precision connectors, and automotive components. If your project requires high-volume production and consistent quality, die casting can deliver both efficiency and superior part performance. Looking to compare die casting vs. investment casting for brass? Consider the balance between production speed, cost, and intricacy of the required brass components.

Investment Casting

Investment casting—often called the "lost wax" process—begins with a wax pattern of the desired part. This pattern is coated with a ceramic shell, after which the wax is melted out and replaced with molten brass. Investment casting produces highly accurate, intricate, and smooth-finished brass parts, making it ideal for jewelry, decorative hardware, and custom engineering components. If you require precise, small-batch, or bespoke brass pieces with complex geometries, investment casting is a leading choice. Interested in understanding when to use investment casting for brass? This method excels for low-to-medium volume orders demanding exceptional detail.

Continuous Casting

Continuous casting is another advanced method in brass manufacturing, where molten brass is solidified while being continuously drawn through a mold. This process creates long bars, rods, and profiles with uniform properties, often used as feedstock for further machining or extrusion. If your application requires brass stock with consistent cross-sections and minimal internal defects, continuous casting is a solution worth exploring.

Considerations Regarding Brass

While brass offers numerous advantages, several important considerations impact its selection, sourcing, and application. These factors are especially relevant for manufacturers, engineers, and end-users who prioritize long-term performance, sustainability, and safety.

Environmental Impact

The environmental impact of brass production must be weighed, particularly in terms of energy consumption and the ecological consequences of copper and zinc mining. Sustainable sourcing and the use of recycled materials can mitigate these effects. Many brass manufacturers now emphasize eco-friendly production practices, including closed-loop recycling and reduced emissions. If sustainability is a priority for your project, inquire about recycled brass alloys and green manufacturing certifications.

Health and Safety Concerns

During fabrication, brass can release fumes if overheated, especially when lead is present. Proper ventilation and adherence to occupational safety guidelines are critical for worker safety. Additionally, not all brass alloys are suitable for potable water or food-contact applications; ensure compliance with relevant standards when evaluating brass for plumbing, kitchenware, or medical devices.

Corrosion and Maintenance

Although brass is renowned for its corrosion resistance, it can tarnish or corrode over time—particularly in high-humidity, coastal, or industrial environments. Protective coatings, regular maintenance, and appropriate alloy selection can extend the lifespan of brass components. Are you seeking advice on how to prevent brass corrosion? Explore options like lacquer finishes, periodic cleaning, and environmental controls as part of your maintenance strategy.

Benefits of Brass

Brass is one of the most versatile and beneficial alloys available to industry, artisans, and engineers. Its unique combination of physical, chemical, and aesthetic properties unlocks broad potential across many sectors. Below are some of the key advantages that make brass a leading material choice:

- Excellent Machinability: Brass alloys, particularly leaded varieties, are easy to cut, shape, and drill, minimizing tool wear and enabling high-speed manufacturing.

- Superior Corrosion Resistance: Brass components resist oxidation and corrosion, making them suitable for plumbing, marine, and outdoor applications.

- High Durability: Brass exhibits outstanding strength, wear resistance, and longevity even in demanding environments.

- Attractive Appearance: With its gold-like luster, brass is favored for decorative features, jewelry, and architectural details.

- Malleability and Formability: Brass can be easily formed into complex shapes, supporting both functional and artistic applications.

- Electrical Conductivity: Brass offers excellent electrical conductivity—second only to copper—making it ideal for electrical connectors, terminals, and conductors.

- Acoustic Quality: Its unique resonance characteristics make brass the material of choice for many musical instruments.

- Non-Magnetic Properties: Brass is generally non-magnetic, which is critical in sensitive electronic, medical, and navigation equipment.

- Full Recyclability: Brass is fully recyclable with no loss of quality, reducing the demand for virgin ore and contributing to a circular economy.

Do you want to compare brass vs. bronze vs. copper? Brass provides an optimal mix of cost, workability, corrosion resistance, and appearance, making it an excellent alternative depending on the application.

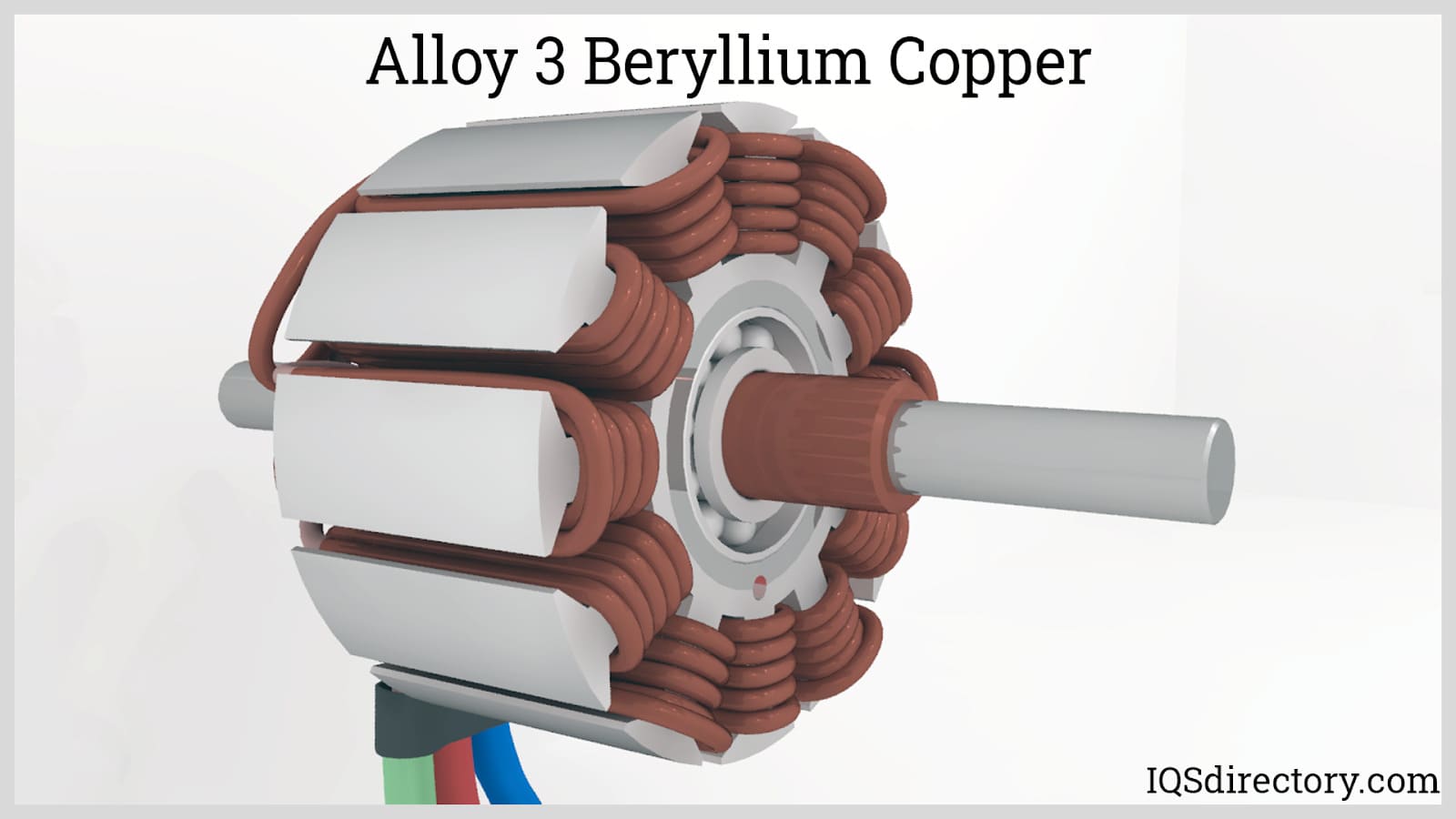

One of the most unique properties of brass is its high electrical conductivity. This makes it an ideal material for electrical components, connectors, and terminals where efficient current flow is required. Copper is widely recognized for its unparalleled conductivity, but brass retains much of this property while offering additional advantages such as increased mechanical strength and improved resistance to corrosion. As a result, brass is a popular choice for power distribution systems, electrical contacts, and precision electronic components.

Applications of Brass

Brass has been integral to human innovation for centuries, with its uses continually expanding across industries. Below are some of the most prevalent and emerging applications for brass alloys. Are you searching for best uses for brass or where to buy brass parts? Explore these categories to match brass properties to your project requirements:

Architecture and Construction

Brass is a preferred material for architectural accents, including door handles, stair railings, kick plates, and lighting fixtures. Its corrosion resistance and elegant finish make it suitable for both interior and exterior use. Brass can also be custom fabricated for bespoke building features, handrails, or façade elements. Interested in custom brass fabrication for construction? Many suppliers offer design-to-installation services for commercial and residential projects.

Plumbing

Thanks to its resistance to corrosion and biofouling, brass is the material of choice for plumbing fixtures, pipe fittings, valves, and taps. Its machinability allows for the production of leak-free, precision-engineered components. If you’re comparing brass vs. plastic for plumbing, brass offers greater longevity, reliability, and higher resistance to temperature extremes.

Electrical Equipment and Wiring

Brass is widely used in electrical connectors, terminals, switches, sockets, and circuit board components due to its excellent conductivity and durability. For reliable, safe, and efficient power transmission, brass is often selected over alternative metals. Are you evaluating brass for electrical contacts? Its resistance to corrosion ensures long-term performance in both commercial and residential installations.

Musical Instruments

Brass is synonymous with musical excellence, forming the backbone of instruments such as trumpets, trombones, tubas, French horns, and saxophones. The alloy’s acoustic properties, workability, and ability to hold a polished finish contribute to the rich sound and aesthetic appeal of brass instruments. Considering brass vs. silver for instruments? Brass is more affordable and offers a classic tonal quality favored by musicians worldwide.

Jewelry and Accessories

Brass’s gold-like color and malleability make it ideal for crafting jewelry, watches, buckles, buttons, and fashion accessories. It is often used as an affordable alternative to gold, with the added benefit of being easy to shape and engrave. Are you seeking nickel-free brass jewelry? Many manufacturers now offer hypoallergenic brass alloys for sensitive skin.

Coins and Tokens

Brass’s durability, workability, and resistance to tarnish have led to its use in minting coins, medals, and tokens for centuries. Its unique color and wear resistance ensure long-lasting value and recognition. When exploring brass vs. copper for coins, brass provides a harder and more corrosion-resistant solution.

Weaponry and Ammunition

Brass is indispensable in the production of ammunition casings, shell cartridges, and firearm components. Its strength, ductility, and resistance to corrosion under extreme conditions ensure reliable performance and safety. Are you comparing brass vs. steel for ammunition? Brass is preferred for its ease of reloading and consistent firing characteristics.

Marine Equipment

For marine applications—such as propellers, shafts, pumps, and fasteners—brass excels due to its resistance to saltwater corrosion and biofouling. Marine-grade brass alloys are engineered to withstand harsh seawater environments, reducing maintenance and extending service life. If you’re searching for best metals for marine use, brass should be high on your list.

Automotive Parts and Accessories

Brass is used in a wide range of automotive components, including radiators, fuel system parts, sensors, terminals, and decorative trim. Its machinability and corrosion resistance make it suitable for both functional and aesthetic applications in vehicles. Looking for OEM brass parts for automotive? Many suppliers offer customized solutions for classic and modern vehicles alike.

Decorative Art and Sculptures

Artists and craftspeople value brass for its workability, ability to hold detail, and resistance to tarnish. It is a popular medium for statues, plaques, inlays, and bespoke art installations. Interested in commissioning custom brass sculptures? Numerous foundries and artisans provide design, fabrication, and finishing services for public and private art projects.

Industrial and Mechanical Applications

Brass is extensively used in gears, bushings, bearings, valves, and fasteners for industrial machinery due to its low friction, wear resistance, and dimensional stability. If you require precision brass components for machinery, brass can provide the right combination of reliability and machinability.

Scientific and Laboratory Equipment

Brass is often found in scientific instruments, laboratory fittings, optical housings, and calibration weights, where stability, non-magnetic properties, and resistance to corrosion are essential. Considering materials for lab equipment? Brass’s dimensional and thermal stability make it a go-to choice for precision instruments.

Choosing the Correct Brass Manufacturer

Selecting the right brass manufacturer or supplier is a critical step in ensuring the success of your project—whether you require raw brass stock, finished brass products, or custom-engineered components. Here’s how to streamline your brass sourcing process using our comprehensive directory:

- Compare multiple brass manufacturers side-by-side using our detailed directory, which provides business profile pages outlining each company’s specialties, production capabilities, quality certifications, and industry experience.

- Utilize our contact forms to request information, technical support, or custom quotes directly from brass suppliers—saving you time and ensuring prompt, personalized responses.

- Leverage our proprietary website previewer to quickly review and compare company websites, allowing you to assess their expertise, product ranges, and customer service standards.

- Submit a single RFQ (Request For Quote) form to contact several pre-qualified brass manufacturers at once, maximizing your reach and expediting your procurement process.

- Review testimonials, case studies, and client references available on each profile page to make informed decisions based on real-world performance and industry reputation.

Are you wondering how to choose the best brass supplier? Consider factors such as product quality, manufacturing certifications (like ISO or ASTM), lead times, customization options, minimum order quantities, and after-sales support. Request samples or technical datasheets to verify that the supplier’s brass alloys meet your project’s requirements for composition, mechanical properties, and compliance with industry standards.

For specialized applications—such as medical, aerospace, or electronics—ensure the brass manufacturer has experience with relevant certifications and regulatory requirements. If you need advice on brass alloy selection or custom fabrication, our network of manufacturers and technical experts is ready to assist with guidance tailored to your unique needs.

Ready to source high-quality brass or request a quote? Browse our brass manufacturer directory to find reliable suppliers, compare capabilities, and connect with experts dedicated to delivering the best brass solutions for your business.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services