To improve a metal’s qualities, it is mixed with another metal or other non-metal elements to form an alloy. Beryllium copper (BeCu) is a metal alloy of copper which is achieved by adding beryllium (ranging from 0.5% to 3%). Typically beryllium is added to increase copper’s strength. The specific grade of beryllium copper depends on the ratio of beryllium to copper and each grade has other beneficial characteristics. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

At ABC Metals, we are dedicated to delivering high-quality copper products that meet the diverse needs of industries worldwide. We work with a wide range of copper materials, from pure copper to specialized alloys, to provide solutions that excel in conductivity, durability, and corrosion resistance.

At Southern Copper & Supply Company, we have built our reputation on delivering high-quality copper products and dependable supply solutions to meet the diverse needs of our customers. We specialize in sourcing, processing, and distributing copper in various forms, from raw stock and sheet material to precision-cut and custom-fabricated components.

More Beryllium Copper Suppliers

Beryllium copper alloys are renowned for their exceptional combination of strength, conductivity, and versatility. The distinction between these grades is based on their electrical conductivity and mechanical strength, making beryllium copper a preferred material across multiple industrial sectors. As one of the strongest copper-based alloys available, beryllium copper is extensively used in demanding environments where reliability, durability, and safety are paramount. Advancements in alloy processing, such as improved casting and enhanced machining, have further broadened the range of beryllium copper applications, including those in the electronics, aerospace, automotive, and energy industries.

Traditionally, machine parts and precision tools have been made of beryllium copper due to its superior mechanical properties. Today, technological developments have made this alloy suitable for more specialized applications, such as high-performance electrical connectors, electronic components, and aerospace structures. Its unique balance of attributes supports critical functions in environments where failure is not an option.

Properties of Beryllium Copper

Beryllium copper and its broad range of alloys exhibit a variety of beneficial characteristics that are highly valued in industrial, commercial, and technical settings. When considering whether to select beryllium copper for your project, it's important to evaluate the detailed properties that set it apart from other copper alloys and non-ferrous metals:

- Superior thermal and electrical conductivity: Beryllium copper offers excellent conductivity, making it an ideal choice for electrical contacts, connectors, and switch components. It ensures efficient heat dissipation and stable electrical performance in high-demand applications.

- High ductility and outstanding formability: The alloy’s mechanical properties facilitate precise machining, forming, stamping, and metalworking processes, leading to better part consistency and reduced waste.

- Non-magnetic properties: Beryllium copper is non-magnetic, which is essential for applications in sensitive instrumentation, MRI rooms, and electronic systems where magnetic interference must be minimized.

- Non-sparking safety: Beryllium copper does not generate sparks upon impact, making it the material of choice for tools and equipment used in hazardous or explosive environments such as oil and gas extraction, mining, petrochemical plants, and grain handling.

- Exceptional durability and wear resistance: It is more durable than most copper alloys and resists wear, galling, and deformation, even under repeated mechanical stress. This attribute is particularly valuable in applications such as industrial springs, connectors, and high-cycle switch components.

- Extreme temperature performance: Beryllium copper retains its beneficial properties in extreme conditions, from cryogenic temperatures to high-heat environments, supporting mission-critical aerospace, automotive, and electronic applications.

- Corrosion and oxidation resistance: The alloy provides superior resistance to corrosion and oxidation, outperforming steel in many environments, which extends component life and reliability.

- Precipitation-hardening capability: Beryllium copper is suitable for precipitation-hardening (age hardening), a process that further increases its strength and hardness, allowing the creation of even-stronger super alloys.

- High tensile strength: Beryllium copper is the strongest copper alloy, with a maximum load-bearing capacity approaching 200,000 psi. This makes it comparable to high-strength steels, particularly after heat treatment.

Are you evaluating materials for high-performance electrical, electronic, or mechanical applications? Explore the unique benefits of beryllium copper alloys compared to other copper alloys to determine the optimal choice for your requirements.

Types of Beryllium-Copper Alloys

The physical and mechanical properties of beryllium copper alloys are significantly influenced by the amount of beryllium and other alloying elements, as well as the specific heat treatment procedures employed by manufacturers. For buyers and engineers seeking to source or specify beryllium copper, understanding these distinctions is crucial for making an informed decision. Beryllium copper alloys are broadly categorized into two main types: high-conductive beryllium-copper alloys and high-strength beryllium copper alloys. The following sections provide a detailed breakdown of each type, including their compositions, key characteristics, and typical applications.

High-Conductive Beryllium-Copper Alloys

High-conductive beryllium copper alloys contain a lower percentage of beryllium, typically ranging from 0.2% to 0.7%. These alloys may also include small amounts of cobalt and nickel to further enhance their conductivity. As their name suggests, these alloys excel in electrical and thermal conductivity, making them particularly well-suited for demanding applications in the energy, electronics, and automotive industries.

-

C17510 or Alloy 3

Alloy 3 is utilized in applications requiring moderate strength, excellent resistance to thermal fatigue, and high electrical conductivity. With a composition of 1.4% to 2.2% nickel and 0.26% to 0.6% beryllium, C17510 is widely specified for use in resistance welding electrodes, power transmission contacts, and high-current switchgear parts where heat dissipation and mechanical reliability are critical.

-

C17500 or Alloy 10

This alloy features a beryllium content of 0.4% to 0.27% and a higher cobalt content of 2.4% to 2.7%. The elevated cobalt level imparts slightly reduced thermal conductivity and melting point compared to C17510, while maintaining excellent strength and hardness. Both C17500 and C17510 are known for their high electrical and thermal conductivity, making them ideal for electrodes, connectors, and components in automotive ignition systems, aerospace connectors, and industrial power distribution systems.

Need help selecting a high-conductivity copper alloy for your application? Contact a beryllium copper specialist or request a datasheet to compare performance and suitability for your project’s needs.

High-Strength Copper Alloys Made of Beryllium

High-strength beryllium copper alloys are engineered for applications demanding maximum mechanical strength and durability. With beryllium content ranging from 1.6% to 2.05%, these alloys deliver exceptional hardness and tensile strength, making them suitable for heavy-duty and precision applications across aerospace, defense, automotive, and telecommunications sectors.

-

Alloy 25 or C17200

The strongest and hardest among beryllium-copper alloys, C17200 (Alloy 25) combines a tensile strength of up to 200 ksi with a beryllium content of approximately 2%. This alloy exhibits steel-like strength while retaining remarkable corrosion resistance and conductivity properties. Alloy 25 is frequently used in plastic injection mold tooling, precision springs, high-load electrical contacts, aerospace fasteners, and critical components where both strength and thermal management are vital. Notably, C17200 lowers the temperature of plastic molds during injection, eliminating the need for additional cooling water and reducing production cycle times.

-

Alloy M25 or C17300

C17300, also known as Alloy M25 or "leaded beryllium copper," contains a small lead addition (0.2% to 0.6%), which enhances machinability without significantly compromising mechanical strength or conductivity. This makes C17300 ideal for manufacturing complex, precision-machined components such as electrical connectors, instrument contacts, fasteners, and bushings, especially in high-volume production environments where tight tolerances and repeatability are essential.

Wondering which beryllium copper alloy type is best for your application? Compare high-strength and high-conductive beryllium copper alloys to determine the right balance of mechanical and electrical properties for your component design or manufacturing process.

Common Applications of Beryllium Copper Alloys

Beryllium copper’s unique blend of properties makes it the preferred solution for a wide range of demanding industrial, commercial, and consumer applications. Its superior strength, corrosion resistance, and electrical performance enable reliable operation in harsh and precision environments alike. Below are some of the most common and significant uses of beryllium copper alloys:

- Resistance welding and spot welding electrodes: Thanks to their high thermal conductivity and wear resistance, beryllium copper electrodes deliver longer service life and consistent weld quality in automated production lines.

- Automotive and aerospace components: Used extensively in high-performance vehicles, aircraft, and communication satellites for springs, bushings, bearings, and precision fasteners, where high strength-to-weight ratio and fatigue resistance are required.

- Springs and spring wires: The alloy’s resilience and fatigue strength make it ideal for producing springs, clips, and electrical contacts that must withstand repeated cycling and vibrations.

- Injection molding and die casting: Beryllium copper is widely used for nozzles, mold inserts, cores, and plunger tips in plastic injection and metal die-casting processes. Its high thermal conductivity ensures rapid heat transfer, reducing cycle times and improving part quality.

- High-reliability electrical connectors: The exceptional conductivity and mechanical stability of beryllium copper support high-speed data transmission and robust connections in telecommunications, data centers, and military electronics.

- Non-sparking safety tools: Hand tools, wrenches, hammers, and screwdrivers made from beryllium copper are essential for work in explosive atmospheres, meeting safety regulations in oil and gas, chemical, and mining industries.

- Mold making and precision tooling: The alloy’s machinability, dimensional stability, and resistance to thermal fatigue make it the material of choice for complex mold components and high-tolerance tooling applications.

- Medical devices and instrumentation: Non-magnetic and corrosion-resistant properties enable use in surgical tools, diagnostic devices, and MRI-compatible components.

Looking for more industry-specific examples? Discover how beryllium copper is used in your sector by browsing our copper alloy supplier directory or contacting an expert for tailored recommendations.

Benefits of Using Beryllium Copper Alloys

When it comes to selecting a material for applications that require reliability, longevity, and top-tier performance, beryllium copper stands out for several compelling reasons. Here are the key benefits that drive manufacturers, engineers, and procurement specialists to choose beryllium copper over alternative materials:

- Unmatched combination of strength and conductivity: Unlike many metals, beryllium copper offers both high mechanical strength and excellent electrical/thermal conductivity in a single material, allowing for lighter, more compact designs without sacrificing performance.

- Extended service life: The alloy’s resistance to wear, fatigue, and corrosion means components last longer, reducing maintenance costs and downtime in critical systems.

- Design flexibility: Beryllium copper can be formed, machined, stamped, or cast into complex shapes and fine tolerances, supporting innovative product development and precision engineering.

- Enhanced safety for hazardous environments: Non-sparking and non-magnetic properties make beryllium copper the safest choice for tools and components used in explosive or sensitive environments.

- Stable performance in extreme conditions: Whether exposed to sub-zero temperatures or high heat, beryllium copper maintains its structural integrity and functional properties, ensuring reliability where it matters most.

Are you weighing the pros and cons of beryllium copper versus phosphor bronze, brass, or other specialty alloys? Request a technical comparison or consult with our materials engineers to identify the best fit for your project.

Factors to Consider When Choosing a Beryllium Copper Supplier

Choosing the right beryllium copper supplier is critical to ensuring product quality, supply chain reliability, and cost-effectiveness. Here are some essential decision factors to keep in mind when sourcing beryllium copper alloys for your application:

- Material certification and traceability: Ensure your supplier provides full certification, compliance with international standards (such as ASTM B194, AMS 4533), and traceability for every batch of beryllium copper supplied.

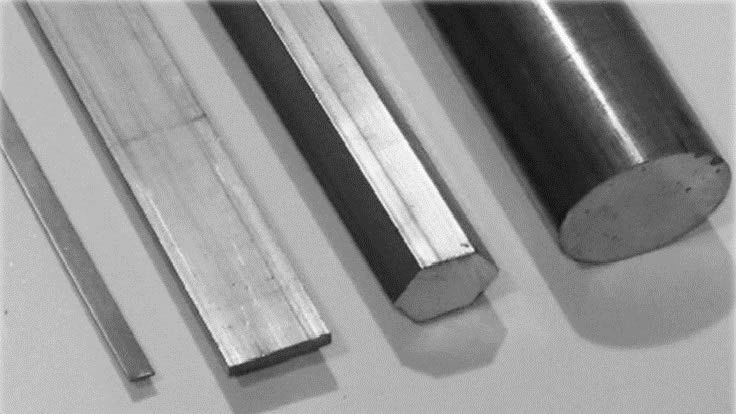

- Manufacturing capabilities and customization: Leading suppliers offer a wide range of forms (sheet, strip, rod, bar, wire, tube), custom sizes, and value-added services such as precision machining, cutting, and heat treatment, tailored to your specifications.

- Technical expertise and support: An experienced supplier can offer technical guidance on material selection, alloy grades, and application engineering, helping you optimize performance and reduce costs.

- Quality control and testing: Ask about in-house testing, inspection protocols, and quality control systems to ensure your components meet stringent requirements.

- On-time delivery and logistics: Reliable suppliers have robust logistics networks and inventory management systems to guarantee timely delivery and minimize supply chain disruptions.

- Competitive pricing and transparency: Request detailed quotes and compare pricing from multiple suppliers to ensure you’re receiving the best value without compromising on quality or service.

To ensure the best outcome when purchasing beryllium copper from a trusted supplier, it is advisable to compare offerings from at least 5 or 6 companies. Use our comprehensive Beryllium Copper Supplier Directory to access detailed business profiles, review each company’s expertise and capabilities, and use our contact forms to request additional information or a custom quote. Our proprietary website previewer allows you to quickly assess each supplier’s specialization, while our streamlined RFQ process enables you to contact multiple beryllium copper suppliers with a single request.

Ready to take the next step? Request a quote or connect with leading beryllium copper manufacturers to discuss your application, technical requirements, and delivery timelines.

Frequently Asked Questions About Beryllium Copper

- What are the safety considerations when handling beryllium copper? While beryllium copper is safe to use in finished form, dust or fumes generated during machining or processing can pose health risks. Always follow recommended safety guidelines and work with certified suppliers who adhere to environmental and occupational standards.

- How does beryllium copper compare to phosphor bronze or brass? Beryllium copper offers higher strength, better fatigue resistance, and superior electrical conductivity compared to phosphor bronze or brass, making it the preferred choice for high-performance and safety-critical applications.

- Which industries benefit the most from beryllium copper alloys? Key industries include aerospace, automotive, energy, electronics, telecommunications, medical device manufacturing, and oil & gas, among others.

- Are custom beryllium copper alloys available? Yes, many suppliers offer custom alloy compositions, tempers, and forms, as well as value-added services such as machining, plating, and assembly.

- Where can I find technical datasheets or material specifications for beryllium copper? Visit our supplier directory or contact leading manufacturers directly for detailed material datasheets, certifications, and technical support.

Still have questions about beryllium copper alloys, grades, or sourcing options? Contact our team of material experts for personalized assistance, or use our supplier directory to connect with the right partners for your needs.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services